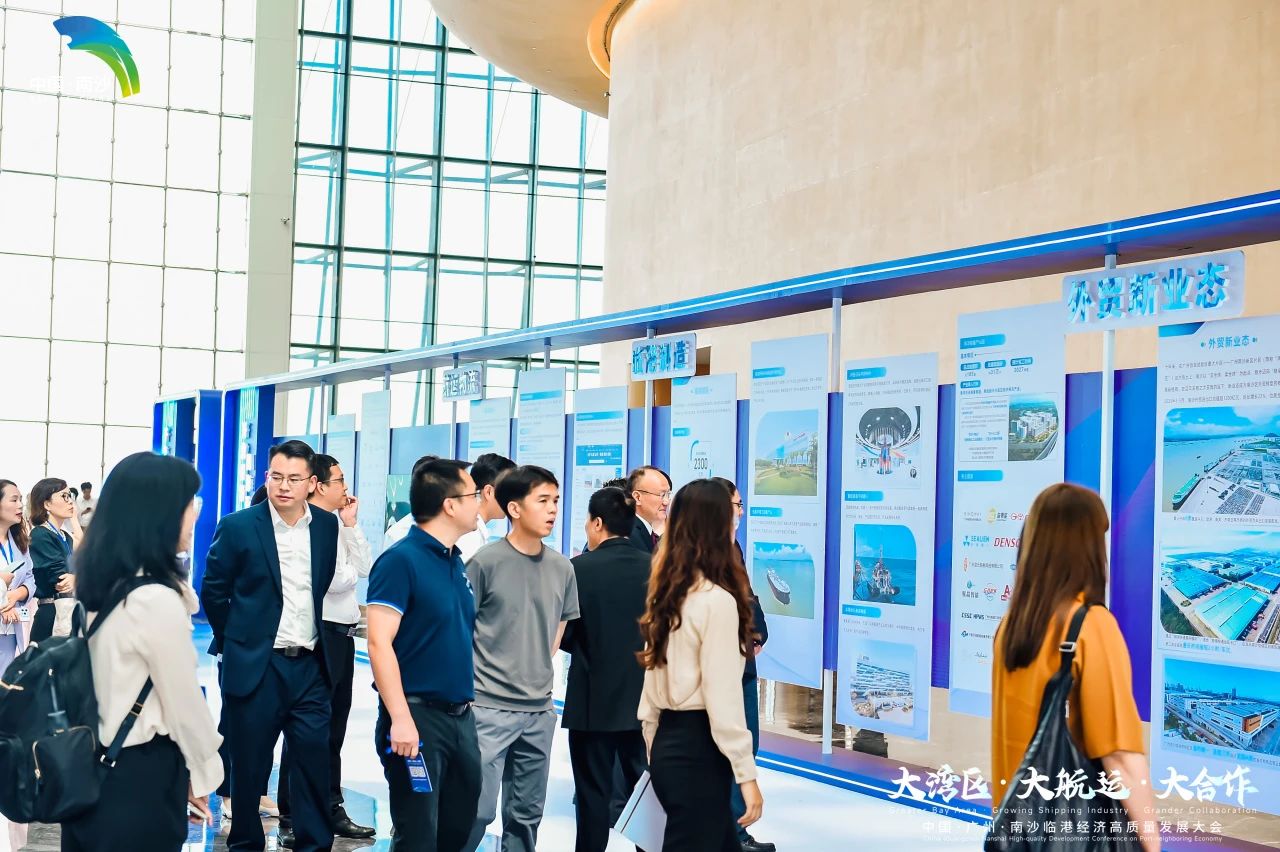

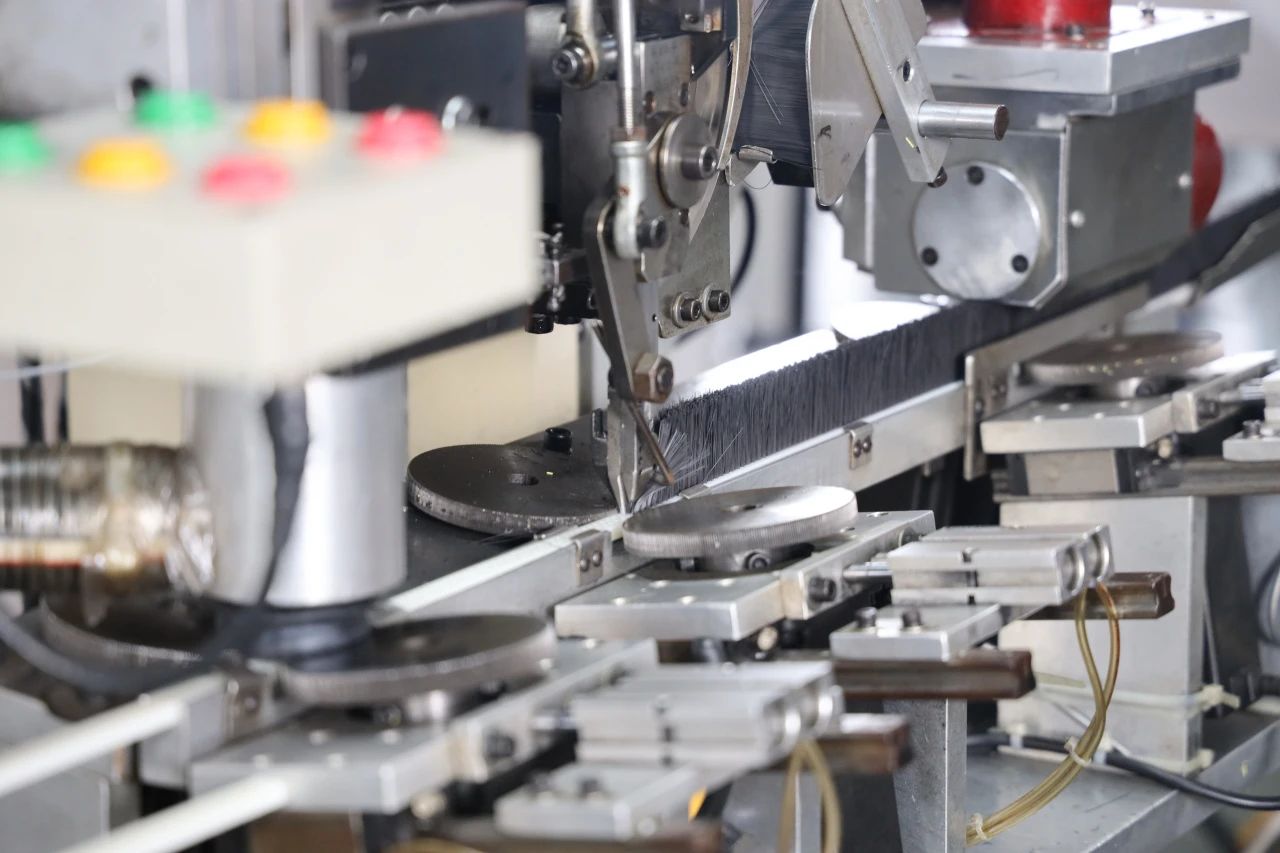

At Guangzhou’s "Greater Bay Area, Mega Shipping, Collaborative Growth" Port Economy Summit, Nansha unveiled ¥7B in signed projects and launched two pivotal platforms: the Greater Bay Area Port Industry Cluster and Shipping Joint Trading Center, marking its leap toward a high-energy port economy. The "Five-Port Synergy" blueprint (Seaport, Airport, Digital Port, Financial Port, Talent Port) accelerates, fueling trillion-yuan port-industrial clusters via global shipping hubs. Amid this maritime industrial surge, AOQUN aligns with core port economy sectors through its "One Core, Multiple Innovations" product matrix: Empowering Air/Sea Ports & Green Shipping High-Performance Brush for Smart Manufacturing (Patent: ZL202210598941.4) 1M+ friction cycles, 2× polishing efficiency, 99.96% yield IATF16949 certified; replaces EU/US/JP tools Applications: Shipbuilding, automotive, aerospace, semiconductors Military/Aviation/Marine Brush (Patent: ZL202210598941.4) 98.7% carbon removal (turbine blades); 3.2mm groove cleaning 45% less downtime; replaces monopolized imports Applications: Warship turbines, military aircraft engines eVTOL Energy-Saving Brush(Patent: ZL202411844819.6) 98.5% air-tightness against turbulence/high-temp dust 40% energy reduction; 30+ aviation certifications Breakthrough: Zero-leakage at wing-fuselage joints With innovative materials, precision engineering, and smart brush solutions, AOQUN drives advanced manufacturing, biopharma, clean energy, and precision processing—powering the Greater Bay Area’s maritime-industrial ascent.

read more

At TSMC’s 3nm production line, a mere 0.5-micron particle can destroy wafers worth millions. SEMI data reveals that global semiconductor fabs suffer $5 billion+ annual losses due to yield gaps from cleaning processes—a stark testament to nanoscale manufacturing’s zero-tolerance for contamination. Nanoscale Cleaning Solutions Breaking Limits AOQUN’s Engineering R&D Center, backed by 20 years of expertise and partnerships with Sun Yat-sen University, Jinan University, and others, has pioneered the Intelligent Damage-Free Pcb Cleaning Brush (Patent: ZL202411907351). This "nano vacuum"-like solution empowers the semiconductor industry to shatter cleaning barriers. ▶ Zero-Damage Precision Withstands 1 million+ friction cycles via ultra-elastic, wear-resistant design. Exceptional flexibility removes contaminants without scratching wafer surfaces. ▶ Revolutionary Contaminant Removal Eliminates stubborn residues (CMP slurry, metal debris) through directional fiber alignment technology, ensuring uniform pressure distribution. This achieves: ✓ 40% higher cleaning efficiency ✓ Zero surface damage ✓ Replaces German/EU/Japanese polishing tools End-to-End Semiconductor Coverage AOQUN’s Chip cleaning solutions span: Front-end: Wafer fabrication Back-end: Chip packaging/testing Advanced applications: Mass IC production, 5G communications, AI chips With 250 million annual capacity, AOQUN meets high-volume, high-precision demands of global semiconductor leaders. Future Focus: Smaller Nodes, Smarter Connectivity AOQUN will advance material science and digital production to tackle cleaning challenges in sub-nm processes and high-frequency applications—empowering the IoT era with micron-perfect purity.

read more

AOQUN Brush has been certified as a "Green Factory" in recognition of its achievements in establishing a green manufacturing system. This distinction underscores AOQUN’s leadership in energy conservation, emission reduction, resource recycling, and smart production. Green Innovation in Low-Carbon Action Integrating sustainability into R&D, AOQUN drives green manufacturing through: ▼ Industry-Academia Collaboration: Partnered with Sun Yat-sen University to develop Aquaculture Filters Brush (Patent: ZL201710365869.X) and with Jinan University on Wear-Resistant Photovoltaic Solar Panel Brush (Patent: ZL202310862044.4). ▼ Standard Setting: Led 8 industry/group standards (e.g., Carbon Strategy Implementation Guide, Carbon Asset Management Framework) and contributed to 1 national standard. Eco-Intelligent Manufacturing AOQUN’s low-temperature continuous segmented brush production technology delivers breakthroughs: ● Zero Emissions: Odorless, dust-free, waste-free production. ● High Efficiency: Annual output of 250 million units with 99.5% product yield. ● Certified Systems: 9 green management systems (ISO 14001) for full life-cycle sustainability. ● Global Compliance: 30+ certifications (FDA, CE, ROHS, SVHC) ensuring "Green Brushes" worldwide. ▼ Carbon-Reducing Green Brushes Deployed across 20 Fortune 500 companies and 30+ strategic industries, AOQUN’s Green Brushes enable: ✓ 99.96% yield in EV precision polishing ✓ 25% higher efficiency in solar thermal cleaning ✓ 93.8% purification rate for bio-filters Future Vision This "Green Factory" milestone launches AOQUN’s next chapter: advancing brush technology to fulfill our mission of "Making the World Cleaner"—delivering smarter, greener solutions for a sustainable future.

read more

In laboratories at Stanford University School of Medicine, a 0.8mm-diameter cell sampling brush accomplishes the once-impossible: capturing 1.5 million viable cells from cervical folds with millimeter precision—redefining the frontier of precision medicine. The 0.8mm "Cell Hunter": Million-Scale Precision Captured Developed through deep industry-academia collaboration with South China University of Technology and Jinan University, AOQUN’s next-generation nano-coated bionic spiral medical sampling brushes merge materials science and precision engineering. Clinically Optimized Design: Fluid-dynamics-enhanced 360° spiral structure. Certified Safety: 30+ international certifications (FDA, CE, ROHS, SVHC). Unparalleled Precision: Isolates lesion cells from cervical folds while reducing tissue damage to <1/3 industry average. Dual Breakthrough: Non-invasive sampling + high-yield capture, providing reliable specimens for 600+ global medical institutions across Europe, Americas, and Australia. Comprehensive Medical Solutions AOQUN offers 300+ variants (0.8–20mm diameter) for: Endoscopic procedures (pediatric bronchoscopy to gastroscopy) Pathological sampling Interventional therapies Postoperative monitoring Future Focus: Molecular Diagnostics & Personalized Care As diagnostics advance to molecular levels and therapies embrace personalization, AOQUN will pioneer next-gen intelligent sampling brushes, collaborating with global partners to co-create precision medicine’s future.

read more

over $17 billion annually Marine Brushes: Armor for Steel Giants Diamond-Coated Disc BrushAOQUN’s R&D team innovated this ultra-elastic, wear-resistant brush. Paired with high-pressure water jets, it cleans deck/hull grooves to — than traditional tools—without damaging paint surfaces (Patent: ZL202311741572.0) 98.7% removal rate0.03N/cm² precision pressure45%High-Durability Polishing Brush RollWithstands , doubles burr removal efficiency, and achieves . Effectively eliminates rust/scale, enhancing metal surface finish. ♦ : 72-hour delivery for urgent EU/US requests— than industry standards. Full-Scale Coverage98% of vessels♦ : 100+ advanced production lines, . Eco-Compliance From scorching equatorial decks to icebound Arctic routes, AOQUN’s empower the shipping industry—safeguarding every ocean voyage

read morescan to wechat

scan to wechat