Industrial brush deburring is a process that removes burrs on the surface of the workpiece by using the brush disc to rotate and instantly rub against the workpiece to generate cutting force. For workpieces with uneven surface within 100mm, the orifice, inner hole, step edge, surroundings and surface of the workpiece can be deburred by using the brush deburring machine. According to the different materials of the workpiece, choose different brush discs to deburr. Cemented carbide is an alloy material made of hard compounds of refractory metals and bonding metals through powder metallurgy. It has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which basically remain unchanged even at a temperature of 500℃. It still has high hardness at 1000℃. Therefore, the corner passivation processing of cemented carbide requires the use of Sweden BP-MX corner passivation polishing brush deburring machine. And cutting tool polishing, edge passivation, deburring processing. By changing the workbench or clamping method, it can not only process flat disk workpieces, but also passivate, polish and deburr the corners of shaft parts. Flat or slightly concave-convex workpieces are evenly processed by abrasive brushes on a planetary light extraction table. Through the rotary motion of the worktable, the workpiece carrier and the brush, the corners of the workpiece in all directions are uniformly passivated and deburred. In this process, the upper surface of the workpiece is also polished simultaneously. Modular design allows special combinations to suit customer's application; compound interchangeable table for maximum flexibility; dry or wet processing possible; automatic compensation for brush roller wear leads to consistency of results; can produce various edge shapes; fully enclosed working environment; touch-screen simple operation interface.

read more

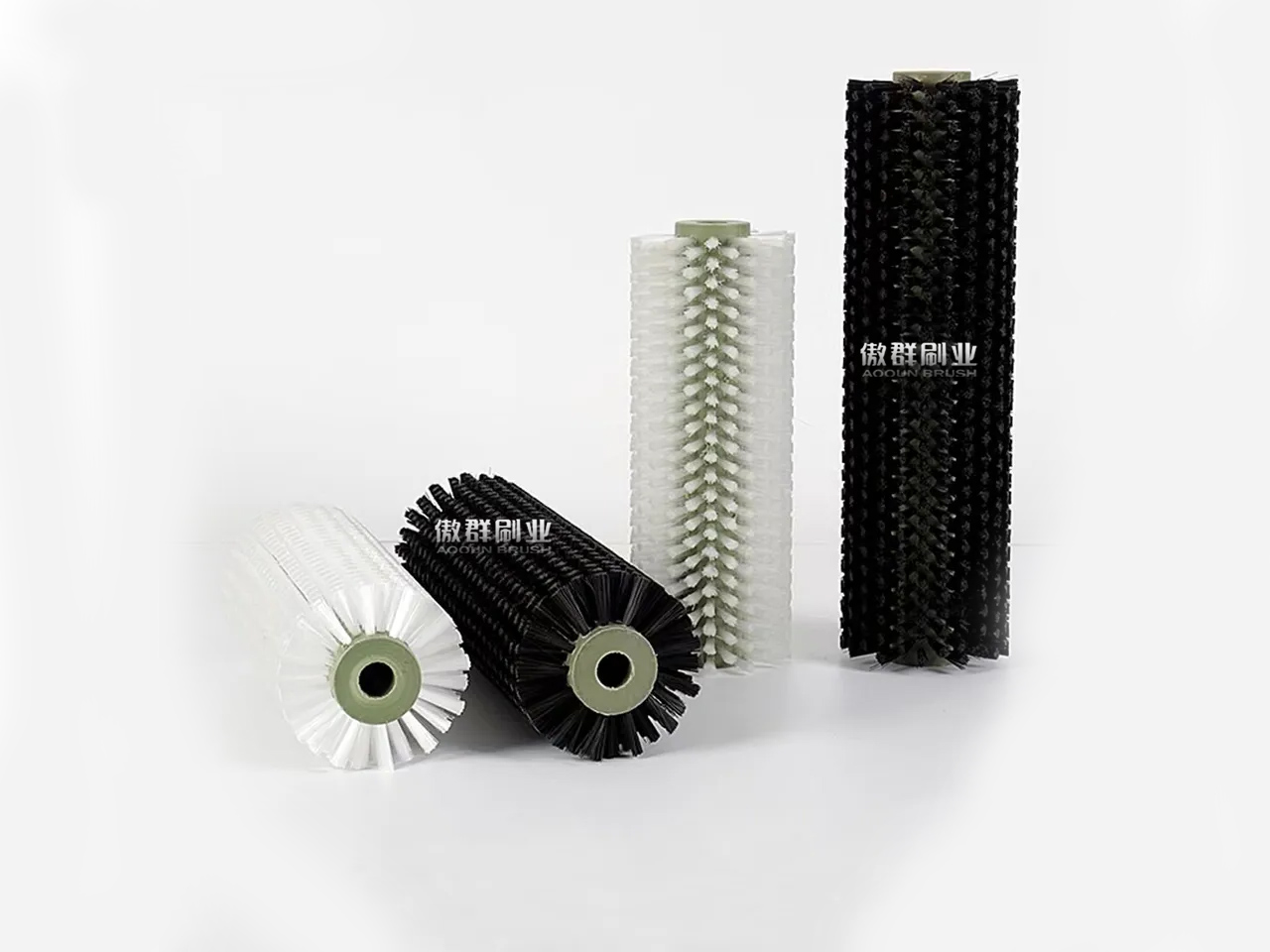

Cleaning machine brush rolls are widely used in industrial production. Cleaning machine brush rolls play a pivotal role in hot-dip galvanizing, pickling, color coating and other production lines. The brush roller manufacturing process in the iron and steel industry mainly includes spiral winding type, internal welding assembly type, and spiral occlusal brush piece assembly type. Cleaning machine brush roller is the most commonly used industrial roller brush. It is generally used for fruit and vegetable cleaning in the deep processing of agricultural and sideline products and general cleaning and dust removal in industry. The requirements for brush wires should be good wear resistance, high elasticity and Anti-corrosion and aging, long-term operation is not easy to deform, if the performance of the brush wire is not good, when the object is placed in a certain position for a long time, it will cause grooves on the brush roller, which will destroy the function of the roller brush, and even cause serious damage. The whole brush roller is scrapped. The application of the brush roller of the cleaning machine: the flow operation of cleaning, removing impurities, conveying, selecting and desalting some leaves, fungi and pickled vegetables. It replaces heavy manual labor and realizes the mechanization of agricultural product processing. The cleaning machine brush roller has the characteristics of simple structure, reasonable design and long service life. It can increase the installation quantity of one-piece brush cover on the effective length of the brush roller shaft by about 10%, and then can fill the bristles with high density and improve the cleaning quality. After the brush roller of the overall cleaning machine is assembled, the outer circle of the nylon brush roller is trimmed and polished as a whole to improve the balance of the brush roller and prolong the service life. In the agriculture and food deep processing industry, during the industrial production of fruits and vegetables, nylon brush rollers are used to clean various fruits, carrots and other agricultural crops. . The bristles are made of nylon temperature-resistant and antibacterial brush wire, which has the characteristics of temperature resistance and antibacterial. The metal wire is made of stainless steel, and the roller shaft is processed by stainless steel parts. Mechanical cleaning, peeling and removal of pesticide residues before fruit preservation.

read more

Industrial brushes are used in different specifications of modern industrial machinery, and the scope of application is also very wide, and the selected manufacturing materials also vary according to the application environment. The following analyzes the product details of industrial brushes. 1. Analysis of the hair planting method of industrial brushes: the hair planting method of the brush roller can be divided into two types: winding type and pressing type. 2. Analysis of the effective hair length of industrial brushes: select according to the service life and workload of the brush roller. 3. Analysis of the outer diameter of the brush roller of the industrial brush: By changing the outer diameter of the brush roller, the workload can be changed. For example, if the outer diameter of the brush roller is increased, the workload will increase; if the outer diameter of the brush roller is reduced, the workload will also become weaker. Industrial brushes are new products that are continuously improved on the basis of civilian brushes. They are mainly used for cleaning, dust removal, polishing, etc. in the process of industrial production. For example: strip transport under high temperature, rough surface treatment, surface cleaning, plate polishing, etc.

read more1. The main purpose of dust removal brushes and dust-proof brushes is to install them at the inlets and outlets of industrial equipment, assembly lines, doors and windows, etc., to prevent dust from getting in through these gaps and polluting equipment and products. Therefore, the requirements for brush wires are It has high elasticity, and the surface of the brush wire is well lubricated. In special occasions, it is best to have flame retardancy, wear resistance, and antistatic functions. For example, the escalator safety brush belongs to the category of dust-proof brushes, but its requirements are higher. 2. The polishing brush is mainly used to deburr and finely polish the surface of the thrown object, so the type and characteristics of the brush wire should be determined according to different requirements. If it is a steel plate with strong hardness, it needs to be electroplated and polished. Yes, the most ideal brush wire should be bronze wire. If it is a general metal material for surface derusting and deburring treatment, then use a steel wire with better hardness. 3. The cleaning brush is the most commonly used industrial roller brush. It is generally used for the cleaning of fruits and vegetables in the deep processing of agricultural and sideline products and the general cleaning and dust removal in industry. Anti-corrosion and aging, long-term operation is not easy to deform, if the performance of the brush wire is not good, when the object is placed in a certain position for a long time, it will cause grooves on the brush roller, which will destroy the function of the roller brush, and even cause the whole The strip brush roller is scrapped. 4. Abrasive brushes are rarely used. Generally, industrial grinding is done directly with abrasive tools such as grinding wheels. These are not within the scope of industrial brushes, but abrasives containing silicon carbide are used for grinding in the textile industry. For wire brush rollers, the mesh number (density) of silicon carbide contained in the abrasive wire should be properly adjusted according to the strength of the fabric to be ground and the effect to be ground. 5. Flocking brushes are used for cleaning, coating, transporting, degreasing, laminating, dusting, dusting, sweeping and other applications. We can customize flocking brushes of various sizes and filament materials to meet your application needs.

read more

The brush roller, as the name suggests, is formed by staple brush filaments (nylon filaments, plastic filaments, metal filaments, pig bristles, horse hair, etc.) on roller-shaped objects. When people use the brush roller, they sometimes find that there are problems of one kind or another, so they question the quality of the product. In fact, as long as the manufacturer and the user pay attention to the following points, the brush roller can be well eliminated. The possibility of problems with roll products. 1. First of all, the brush roller must be cleaned and packaged before leaving the factory, because a lot of broken hair will be produced in the process of planting and flat wool, so the brush wire should be combed before packaging, and the broken hair should be cleaned clean. 2. During the transportation from the manufacturer to the user, in order to prevent sundries and dust from impregnating the brush filaments, packaging boxes, bags and other packaging materials should be used for packaging to prevent damage to the brush roller. 3. Be careful not to expose the brush filaments to the outside (without any packaging) or put them on the ground or in other polluted environments before they arrive at the manufacturer and are not used. 4. Place a cushion on the shaft head of the brush roller to keep the brush filaments upright and clean.

read more

The material selection of industrial brushes is very important to the service life of industrial brushes and the effects of polishing, dust removal, surface treatment, etc., so the main materials generally used are steel wire, copper wire, stainless steel wire, nylon wire, plastic wire, abrasive wire, horsetail hair , bristle, sisal and so on. There are many industrial brush products, the simple classification is as follows: brush roller, wire brush, strip brush, belt brush, disc brush, spring brush, nylon brush, rubber roller, sponge absorbent roller, sanitation Car sweeping brush, fireplace chimney brush, bottle washing brush pipe brush, fruit and vegetable cleaning machine brush roller, textile printing and dyeing industry brush, ceramic glaze line brush, glass cleaning machine brush roller, paper printing equipment rubber roller, anti-static Brushes, metal polishing abrasive brushes, metal pickling brush rollers, automatic shoe polisher brush wheels, etc., and other special brushes. 1. Nylon roller brush: brush body nylon 6 or 66, nylon bristles 1010 Specifications: brush body diameter φ30-φ500mm, hair length arbitrary, bristle wire diameter φ0.10-φ1.0 2. Stainless steel roller brush: brush body stainless steel, bristle stainless steel wire Specifications: φ50-φ500mm, arbitrary hair length, bristle wire diameter φ0.10-φ1.0 3. Nylon spiral roller brush: brush body nylon 6 or 66, nylon bristles 1010 Specifications: The diameter of the brush body is φ20-φ500mm, the length of the bristles is arbitrary, and the diameter of the bristles is φ0.10-φ1.0. The angle width can be made according to the drawing. 4. Stainless steel spiral roller brush: brush body stainless steel, bristle stainless steel wire Specifications: φ30-φ500mm, arbitrary hair length, bristle wire diameter φ0.10-φ1.0. The angle width can be made according to the drawing. 5. Nylon roller brush: brush body nylon 6 or 66, nylon bristles 1010 Specifications: brush body diameter φ60-φ500mm, hair length arbitrary, bristle wire diameter φ0.3-φ1.0 6. Nylon board brush: brush body nylon 6 or PVC, nylon bristles 1010 Specifications: The width of the brush body is 8-300mm, the length of the bristles is arbitrary, the diameter of the bristles is φ0.10-φ1.0mm, and the length is arbitrary. 7. Stainless steel disc brush: brush body stainless steel, bristle stainless steel wire Specifications: The diameter of the brush body is φ100-φ500mm, the thickness of the brush body is 10-30mm, the length of the bristles is arbitrary, and the diameter of the bristles is φ0.5-φ1.2mm.

read morescan to wechat

scan to wechat