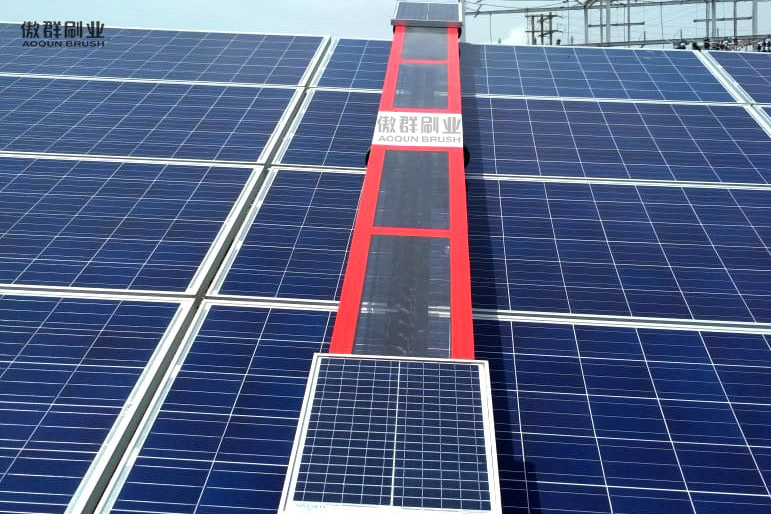

With the widespread use of solar panel cleaning brushes and photovoltaic cleaning robots, many people know that photovoltaic equipment needs to be cleaned regularly. Do you know why the cleaning of photovoltaic equipment is so important? For long-running photovoltaic power generation systems, the impact of panel dust on it should not be underestimated. The dust on the surface of the panel has the function of reflecting, scattering and absorbing solar radiation, which will reduce the transmittance of the sun, resulting in a decrease in the solar radiation received by the panel, and the output power will also decrease. Its effect is proportional to the cumulative thickness of the dust. Rotary Brush Solar Cleaning Brushes In addition to affecting the solar radiation absorption of the panel, dust also affects the photovoltaic module, which becomes the thermal insulation layer of the module, the service life of the junction box and the solar panel. When the junction box and the battery panel are in a high temperature state for a long time, it is easy to produce a high temperature of more than 100 degrees, and it will cause a short circuit in the serious. In addition to the impact of dust on photovoltaic equipment, glass panels are also susceptible to acid and alkali corrosion products. In some areas with acidic rainfall, photovoltaic glass panels are easily corroded by rain and form corrosion marks on the surface. The glass panel corroded by rainwater is prone to diffuse reflection, which affects the spread uniformity of solar radiation. Therefore, it is very important to clean the solar panels regularly to reduce losses.

read moreInner hole polishing is also called deep hole polishing. It is usually a machining method that reduces the roughness of the inner hole by mechanical, electrochemical, electrical spark and plasma methods, so that the surface of the hole is smooth and flat. Starting from the basis of existing technology and cost, most companies use inner hole polishing twisted wire brushes for polishing work. Aoqun Polishing Brush Why choose to use a polishing rod for polishing work? We usually use electrochemical polishing in our lives, but this method is difficult to operate, quality inspection is relatively troublesome, and it takes more man-hours. If the polishing method of EDM is adopted, although the machining accuracy is high and the polished surface is relatively smooth and flat, it will also consume a relatively long working time. Therefore, most manufacturers adopt the method of mechanical polishing. Mechanical polishing usually customizes the internal hole polishing twisted wire brush of the appropriate size through the twisted wire brush manufacturer, and uses physical methods to perform the work of polishing and deburring, which is welcomed by enterprises. Aoqun twisted wire brush manufacturers have nearly 20 years of experience in brush making, and can tailor the inner hole polished twisted wire brush of the appropriate size for the manufacturer, and adjust the details according to the actual use situation to create a more suitable production twist for your wire brush.

read more

Strip brushes are also called brush strip, industrial strip brushes, etc., which are made by pressing iron sheet, aluminum strip and stainless steel strip as the base of the strip brush by adding corresponding filaments to it. It has a wide range of applications. It can be used in escalators, doors (such as household doors, industrial doors, fast doors, rolling doors, revolving doors, screen doors, etc.), and can also be used in desks, household vacuum cleaners, cabinets and even industrial machines on the device. Therefore, the main function of the strip brush is safety and anti-pinch, sealing and dust prevention, dust removal and decontamination, polishing and polishing, etc., both in industry and daily life, have given a significant role. Since the application range of the strip brush is so wide and its effect is so great, how should we choose the right strip brush? Strip Brush 1. Strip brushes made of different materials should be selected according to the different use environments, so that their service life can be longer. For example, the anti-pinch strip brush installed on the escalator can be made of nylon because its hair will be softer and recover faster. 2. It is necessary to choose a strip brush with better tensile strength. No matter what kind of equipment it is installed in or what role it plays, the strip brush is mainly due to the fact that the filaments cannot be dropped, otherwise everything will become empty talk. Therefore, It is your best choice to choose a brush with high tensile strength. Aoqun Brush Industry, as a large-scale strip brush manufacturer with more than ten years of R&D and production experience, can customize strip brushes of various sizes and functions for you. The tensile force of the strip brush can be ≥6KG, which can more effectively prevent hairs. Drop, achieve the desired effect you want, more customized solutions, please contact Aoqun Brush Industry.

read more

We usually hear that there are two names: strip brush, and brush strip. In fact, these three names refer to the same product. There is a machine passing through the iron base, and a fastening thread is placed in the middle. A kind of brush product that is symmetrically pressed, because the produced shape finally shows a strip shape, so it has the above three names. Later, as its application range became wider and wider, more pronouns appeared, such as brush rod, rod brush, long brush, straight brush and so on. There are many names for it. For example, it is often used with aluminum alloy brackets, so some people also call it aluminum alloy strip brushes and hair brush strips. According to different shapes, they can be divided into h-shaped, F type, T type aluminum alloy brush, etc. Strip Brush Seal Another example is the difference in the scope of use, some of which are cabinet strip brushes, escalator strip brushes, splash-proof strip brushes, etc. Therefore, when we see strip brushes and brush strips again, we probably know what kind of brush they are. Aoqun Brush Factory has custom-made brush strips for many years, and can customize strips of various specifications and sizes for you. For more customization details, please contact us.

read more

Why add halogen-free environmentally friendly flame retardant? Flame retardants contribute directly to saving people's lives. In most cases, plastic polymers can cause or spread flames, because they are organic compound plastics. When heated, they can decompose into unstable flammable products. How much do you know about Aoqun flame retardant nylon strip brush seal? Flame Retardant Nylon Strip Brush Seal Currently, flame retardant strip brush sea is divided into the following grades (UL94) according to different countries and no use scenes: 1. HB: The lowest grade requirement among flame retardant grades. For samples with a thickness of 3-13 mm, the burning speed is less than 40 mm/min, and for samples with a thickness of less than 3 mm, the burning speed is less than 70 mm/min; or at the mark of 100 mm. Extinguished before. 2. V-2: After two 10-second burning tests on the sample, the flame goes out within 30 seconds. Can ignite cotton wool under 30cm. 3. V-1: After two 10-second burning tests are performed on the sample, the flame goes out within 30 seconds. Can not ignite cotton wool below 30cm. 4. V-0: After two 10-second burning tests are performed on the sample, the flame goes out within 10 seconds. No burning objects should fall. Aoqun Brush's flame retardant strip brush sea has reached the highest level and can provide third-party inspection reports.

read moreOne type of vent seal that many people use under the door is the door seal strip brush. The seal strip brush is made of wood, metal, vinyl or other materials, and the bristles are swept along the edge of the seal. The panels and bristles, which can be synthetic or natural, are like other types of ventilation seals, helping to block cold air. Door Seal Strip Brush Since the brush assembly is flexible, it can also easily sweep across the floor when the door is opened or closed, providing simple operation while also providing decent wind-dry protection. Here are some tips to keep in mind to help you get the maximum sealing effect. 1. Look for a door sweeper with a double-row sealing strip brush 2. Install the door seal brush on the right side For doors that swing inward, install the sealing strip brush on the inner bottom edge. If the door swings outward, connect it to the outer bottom edge of the door. 3. Use a mohair brush to seal In the long run, you may be most satisfied with the mohair door brush seal. They may be slightly more expensive, but mohair can block airflow very well. Mohair is naturally antibacterial, and the fiber is easy to absorb and release water, and it is also more durable. Mohair is the most durable animal fiber. F-shaped door seal brush strip Aoqun sealing strip brush can be directly assembled on the aluminum alloy base, and can be directly attached to the bottom of the door, which is both sealed and convenient. The sealing effect of the Aoqun sealing strip brush is very good. It is made of pure nylon wool. The flexibility and resilience of the wool are as high as 99.99%. It is not easy to deform and still has a good sealing effect after repeated use.

read morescan to wechat

scan to wechat