You must know that as far as your gun is concerned, skipping some cleaning procedures is harmful to your gun. If you have the habit of being lazy in cleaning, the inside of your gun will become a paradise for bacteria, and even bacteria will grow. So how to use 22 cleaning brush? step 1 There is no need to put the gun in warm water first. 22 The cleaning brush is so efficient that there is no need to immerse the gun in water before cleaning. Unless it is an old gun with years of dry dirt in it, it should be immersed in water, preferably overnight. Step 2 Apply detergent on 22 cleaning brush. Step 3 Rinse the muzzle under the faucet, and then brush off the dirt. To develop a habit, you should use the gun 22 cleaning brush offen and mold will not enter the gun. Aoqun gun brush is made of tough pure nylon wool (PA6/PA66) and 304 stainless steel twisted. The brush will not have sharp parts and will not scratch the gun during cleaning. The head specially designed for gun cleaning can penetrate deep into the gun and touch every sanitary corner.

read more

Mr. Zhang from Foshan called us: "I want to find some inexpensive 12 inch bottle cleaning brushes. Can you provide them to me? Because the price of the previous cooperative dealers has been unstable, the price has increased greatly, makes my purchase cost continue to increase and profits reduce a lot." We immediately introduced to Mr. Zhang that we are experienced in wine bottle manufacturing for many years. AOQUN also proudly formed a long-term cooperative relationship with high-quality raw material suppliers and signed an annual supply agreement with them to keep the price stable. Therefore, even if the price of external raw materials is not stable, the quality and price of our 12 inch bottle cleaning brush products will remain consistent in the market. According to Mr. Zhang's request, I immediately customized 10 12 inch bottle cleaning brush for his confirmation. After receiving the 12 inch bottle cleaning brush, Mr. Zhang said happily: "Your 12 inch bottle cleaning brush samples and price are exactly matched with my requirements. So I will no longer worry about the fluctuation of procurement costs, and my customers are also very happy for that. They have already placed an order for 5,000 pcs and will be 10,000 pcs in the near future. Please help with the raw material in advance."

read more

Manager Ou is the manager of a decoration company in Guangdong. Recently, he received a new project from Vanke and was responsible for the decoration of the sample room and the later project.Because it is a high-end residential area that uses wooden floors, the self-adhesive brush seal used before has been installed and used for a period of time, and the wooden floor has been scratched. Now that he has received a written rectification letter from the real estate owner, Manager Ou is very headache. After searching for experts who knew about Aoqun, he brought samples directly to Aoqun. Mr. Chen from Aoqun received Manager Ou. After understanding the situation and carefully inspecting the original self-adhesive brush seal, he found that the original brush wire was made of PP and the wire diameter reached 0.3mm. The PP itself was harder. If the upper wire diameter is too large, it will be harder. Rubbing on the floor often, it will scratch the floor after a long time. Mr. Chen suggested that Manager Ou directly change the material, adopt a more flexible and resilient PA material, and then reduce the wire diameter to 0.2mm, which can fundamentally solve the problem of self-adhesive brush seal scratched floors. Later, at the request of the manager of Europe, the samples were sent for testing on the next day. After 15 days of replacing the self-adhesive brush seal in the sample room, Manager Ou was affirmed by the developer for the proper improvement of the self-adhesive brush seal in the sample room, and directly signed the later renovation contract. Manager Ou also decided to replace all self-adhesive brush seals with Aoqun, and placed an order.

read more

The vacuum cleaner brush cleaning tool is used in the cleaning industry, so I believe that everyone is familiar with the vacuum cleaner brush cleaning tool. The vacuum cleaner brush cleaning tool is wear-resistant and does not shed hair. In other words, it requires the vacuum cleaner brush cleaning tool to resist tension. The vacuum cleaner brush cleaning tool that does not meet the tensile requirements cannot meet the customer's use effect. The shed hair will affect the vacuum cleaner's sealed vacuum effect and cannot absorb dust. Aoqun Brush Industry's tensile force standard for vacuum cleaner brush cleaning tool is: the tensile tester tests the filaments vertically upwards, and no filaments fall off within the tensile force range. The length of the wool yarn is 10mm, and the pulling force is ≥6kg; the pulling force of about 200 wool yarns is ≥10KG, and there is no pulling phenomenon of the wool. It also passed the customer's high-speed back and forth rubbing one million times without deformation and no hair loss test. Product quality has been recognized by many customers. Aoqun Brush makes every vacuum cleaner brush cleaning tool carefully. Carefully select materials and manufacture with care, and strive to provide customers with a vacuum cleaner brush cleaning tool that is wear-resistant, lint-free and deformed. Over the years, Aoqun has in-depth research on customer requirements and provides customized vacuum cleaner brush cleaning tool services for more than ten industries. Vacuum cleaner brush cleaning tool of various materials, shapes and uses can be tailored to your equipment.

read more

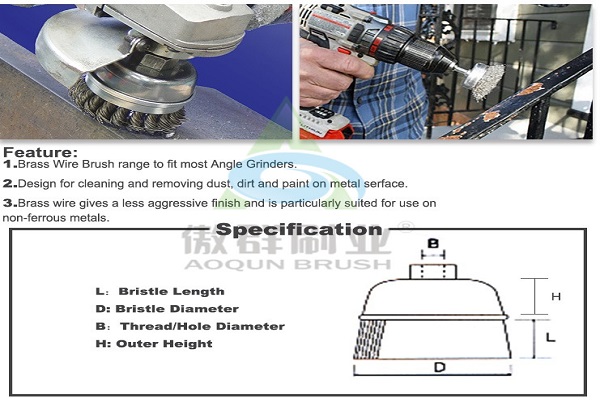

Mr. Li, the R&D director of a world-renowned brand manufacturer, calls to inquire whether Aoqun can produce cleaning brush on drill? Customer service Xiao Liu was very happy to tell Mr. Li that Aoqun Brush is a high-tech company integrating R&D, production and sales. With more than 20 years of senior industry experience, products are exported to more than 50 countries and involve more than 20 industries. This leaning brush on drill is professionally designed and developed for well-known foreign brands. After several years of testing and verification by customers, the customers are very satisfied. Another feature of Aoqun Brush is that it can be customized for customers, even if there is no drawing, as long as there is a sample. Mr. Li immediately sent samples of this cleaning brush on drill. Aoqun engineers immediately evaluated and determined that it can be produced according to the drawings. It takes about 7-10 days to open the mold. The brush recommends PA. Mr. Li was very happy when he heard this. Originally, this cleaning brush on drill had to be imported, but now it can finally be purchased domestically, saving time and time. Buying professional cleaning brush on drill is for Aoqun.

read more

In October, we received an e-mail from Ada, UK. She said that the infant bottle cleaning brushes ordered from other countries were not good, the bottom of the bottles could not be cleaned at all, and the bottle body was not cleaned properly. A lot of complaints from end customers, resulted in a decrease in orders. Ada asked if we could produce a infant bottle cleaning brush that meets their requirements. Splendar, our gold-medal customer service, communicated with Ada in a minute after receiving Ada's e-mail and learned that the previous suppliers had shortened the total length and filament length of infant bottle cleaning brushes in order to save costs, resulting in unclean cleaning. Our technical engineers have increased the length of the infant bottle cleaning brush by 60 mm to ensure that it can be cleaned to the bottom, and the length of the filament has increased from 30 mm to 80 mm to ensure that the surroundings inside bottles can be cleaned well. Ada was very supportive of our proposal and paid the sample fee. We sent him the samples three days later. Five days later, Ada received the samples and was particularly satisfied with sample inspection and praised us for professionalism. She said: "Although your price is relatively expensive, but the infant bottle cleaning brush design and clean performance are excellent." Finally, Ada sent us a purchase orders for 50,000 infant bottle cleaning brushes.

read morescan to wechat

scan to wechat