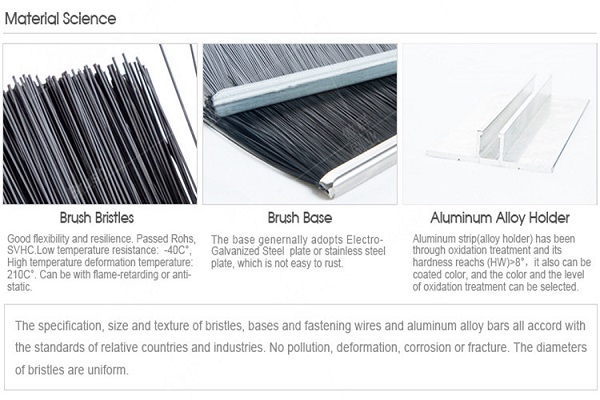

Electronic cigarettes, also known as electronic cigarettes, electronic cigarettes, virtual cigarettes, and electronic atomizers, are mainly used to replace cigarettes and assist smoking cessation. E-cigarettes are cool in appearance. They can suck out smoke, taste and feel like cigarettes, and have more diversified tastes. In order for e-cigarettes to last longer, you need to use e-cigarette small cleaning brush. What are you still confused about? High quality? Aoqun reveals the secret for you. 1: Aoqun's high-quality e-cigarette small cleaning brush is made of pure nylon wool, which has good resilience and can remove tobacco residue stains. 2: Aoqun's high-quality electronic cigarette small cleaning brush is made of 304 stainless steel, which has good elasticity, is not easy to deform, and is durable 3: Some materials of Aoqun's high-quality electronic cigarette small cleaning brush have passed ROHS10, SVHC and other certifications, which are safe and non-toxic. Smoking is harmful to health, we should reduce smoking. Similarly, if the electronic cigarette is not clean, it will affect the taste and service life. Aoqun focuses on the customization of high-quality and large-volume electronic cigarette small cleaning brushes, and actively provides customers with suitable and accurate customized solutions that meet the requirements of use.

read more

Vincent, a customer from the United States, said that he wants to buy a bottle cleaning brush narrow neck. The time limit for receiving goods is within 2 days. He asks us if we can meet his requirements in terms of delivery. After in-depth communication with Vincent, we learned that he had bought a brush in China before, but the shipment was always delayed. On one hand, we guarantee that this lead time will not be a problem for us, because we have a stable freight forwarding channel to ensure that the goods arrive quickly. On the other hand, if our timeliness does not meet Vincent’s requirements, the courier fee can be deducted from the bulk order. In addition, when we sent urgent orders to many other big customers, we did not delay, and the shipment timely rate was 99.99%. Subsequently, Vincent said that he will place first order of 500 bottle cleaning brush narrow neck. After 1 month, we received an email from Vincent "Your courier delivery is very fast and we received the bottle cleaning brush narrow neck within 2 days! We hope that we can have a long-term cooperation”. Vincent placed another order of 5000pcs right after email.

read more

Miss Guo, who bought brush pile seal suppliers, recently encountered an annoyance. The two ends of the brush always shed hair, and the customer complained that the phone kept ringing. The ever-changing and helpless Miss Guo searched to see which brush pile seal suppliers are good, and wanted to buy some to see if it could improve the current situation. After some searching, Ms. Guo hasn't determined which brush pile seal supplier Hershey was attracted by Aoqun's brush pile seal suppliers and clicked in. She found that Aoqun's evaluation was very good, so she directly contacted customer service. After learning about the current situation of Ms. Guo, the customer service told Ms. Guo that the two ends of the hair fell off. The general situation was that the two base iron sheets were not compressed after the brush pile seal suppliers were interrupted. Aoqun has been focusing on researching and making brushes to solve the needs of customers. For this problem, Aoqun chooses four punches to cut the length faster than the normal factory cutting pliers. The most important thing is that the end of the base is very pressed after the length is cut. Tight, no gaps. Aoqun also deliberately grinds out two sharp edges at the end to prevent injury to the hands. After hearing what the client said, Miss Guo felt that she could give it a try and place the order directly. Half a month later, Ms. Guo placed an order again and contacted Aoqun customer service. Before, I always hesitated to buy brush pile seal suppliers, but now I don’t hesitate anymore. Aoqun’s quality leverage has finally improved the current situation of hair loss. , And very grateful to Aoqun.

read more

I often hear feedback from customers. The products of other peers are also nylon record cleaning brush, but the price of Aoqun is always higher than that of others. What is the reason? In response to this question, Aoqun people have something to ask, can you really tell the difference between real nylon and mixed nylon? First of all, nylon filament record cleaning brush is a more commonly used brush product. The main component of nylon filament is polyamide, commonly known as nylon (Nylon), or PA for short. It contains repeating amide groups on the molecular backbone—[NHCO]— The general term for thermoplastic resins. The wool used in record cleaning brush is usually PA6 and PA66, which occupy a relatively large capacity in the market. The pure nylon filament record cleaning brush has good elasticity and the rebound rate is as high as 99.9%. In addition, the nylon filament record cleaning brush has good anti-ultraviolet, anti-aging resistance, low temperature of minus 50 degrees, and outdoor high temperature environment of 40 degrees, ensuring good performance and maintaining value. The nylon wire record cleaning brush is clean and refreshing. After burning, the inner flame is light blue and the outer flame is yellow. The smell is fresh and not pungent. As a company with 20 years of experience in research and development and production of nylon filament record cleaning brush production customization, Aoqun can customize high-quality brush products that suit your use according to your needs, and provide you with a one-stop nylon industrial brush Use the plan, and consult Aoqun professionals for more details.

read more

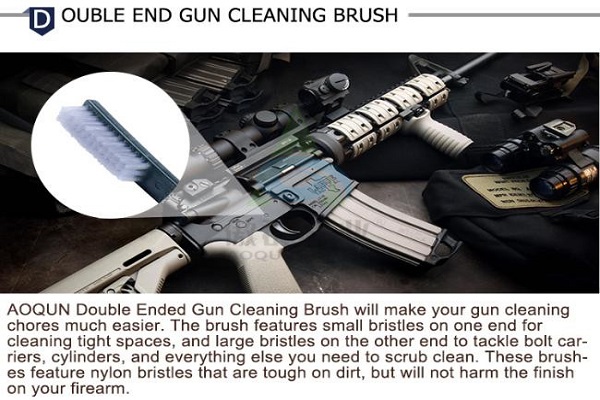

Choosing the right gun cleaning brush is the key to ensuring safe and effective cleaning. If you use a gun cleaning brush with a slightly larger diameter, the bristles will be bent, which may cause the wallpaper to wear out because the gun cleaning brush is too large. Brushes with too small diameter cannot be in close contact with the cleaning surface, so that the cleaning is not clean, leaving contaminants. Only gun cleaning brush with matching size can fully remove debris and ensure the best function. This is why you should choose the right gun cleaning brush, and don't underestimate the consequences of the wrong size. A small move can lead to a big disaster, and the same is true for a wrong parameter. Don't lose the big because it is small, because the consequences may not be what you can bear. If you don't know how to choose the right gun cleaning brush, look for Aoqun, they are definitely your right guide.

read more

Mr. Liu from Hong Kong found our company via his friend's introduction. He hopes to purchase a large number of bottle cleaning brush long handle. What he is most worried about is the quality problem, because the quality of a batch of bottle cleaning brush long handlees purchased before in other company is completely unsatisfactory and the loss of Mr. Liu is very heavy. He hopes that there will be no more quality problems. After learning about Mr. Liu's needs, we sent Mr. Liu our video, pictures of quality inspection process to him, to show the rigor of our production and quality inspection. We also invited Mr. Liu to our factory for personal inspection, hoping to let Mr. Liu know more about the quality of my bottle cleaning brush long handle. Our bottle cleaning brush long handle meets the requirements of ISO9001-2015 quality management system and has 39 product procedures. We will never let any low-quality product to get into the market. Mr. Liu personally came to our company and tested many times; our bottle cleaning brush long handle did not have any quality problems and meet the quality inspection standards of Mr. Liu. On the same day, Mr. Liu directly placed an order for 10,000 bottle cleaning brush long handlees to us.

read morescan to wechat

scan to wechat