After receiving email feedback from German Jim customers in April, the sample of surgical brushes for sale ordered from other countries was inconsistent with the quality of large goods, which was returned directly by customers, resulting in large direct and indirect economic losses. Our sales customer service Mary replied in time 1 minute after receiving the customer email, and Jim learned the actual situation. It turned out that the surgical brushes for sale samples ordered from other countries were very soft, but the big goods received were really hard, not only scraping the test tube, but also being detected by customers to use different materials. The original sample wool is nylon silk, the bulk is PBT silk. Mary sent the certificate of our``Contract and Credit-keeping Enterprise'' to Jim to ensure that we will execute it in accordance with the contract. and sent pictures of customers' praise to Jim. Jim's confidence in us increased, but asked us to send him 50 samples. Three days later, Jim received the surgical brushes for sale sample, the first time carried out the test, found that the sample quality provided by Aoqun was very good, received 500 antenatal sample orders on the same day, we delivered the goods on schedule. Jim found that the quality of both 50 and 500 samples was the same, and said that they were handed over to Aoqun production and placed 50, 000 orders directly to us.

read more

Roger, from New Zealand, says he found his pride on Google. He wants to buy a batch of surgical brushes for sale. Roger said he had previously purchased them from a manufacturer in Anhui, China, but the tube brushes were of very poor quality and were not durable after use. He was very angry and decided to change suppliers. Roger asked Aoqun if he could provide a surgical brushes for sale of good quality. Our gold medal customer Omega told Roger, that Aoqun is an expert in the manufacture of brushes and the first manufacturer in China to formulate the quality standards of brush products. It has received extensive praise from customers in all regions of the world and has become a role model and customer brush inspection standard for its peers. The thickness of the surgical brushes for sale is uniform and the tolerance of hair thickness is ±0.2 mm. Appearance such as laser cutting, neat, smooth, clean. Don't lose hair, it's 10 times stronger than a bunch of hair. Roger was very happy after listening, and then sent us pictures and drawings of his large test tube. Two days later, Aoqun was proofing according to Roger specifications and size requirements, and repeatedly tested it. After using the hair, the surgical brushes for sale was sent to Roger. A month later, Omega received another call from Roger: the feedback from this surgical brushes for sale was very good after it was put on the market. Cleaning is simple and convenient, and the cleaning effect is very good, and the important thing is that there is no hair loss. Roger also said that he has received advance orders from many customers and that the brush has a good prospect. He is going to place 8000 orders.

read more

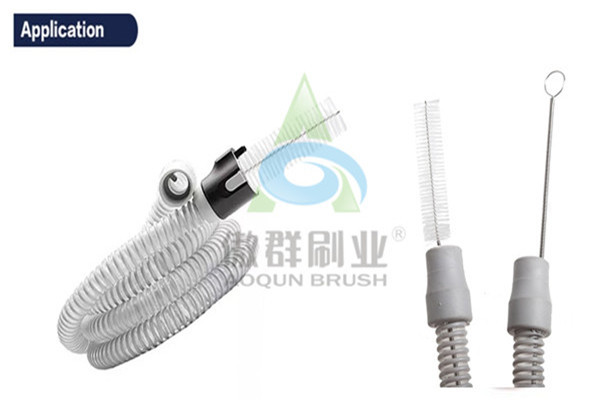

We received an inquiry from the American customer Joe, he said that he would purchase a batch of deluxe flexible stainless cpap tube cleaning brush slimline. He have previously purchased CPAP tube brushes from one of our Chinese manufacturers, but the cleaning performance is not good enough. Joe said that what he needs now is a cleaning brush that cleans the CPAP tube and the oxygen mask,he asked us if we could produce it. We know that CPAP tubes need to be cleaned regularly, because the moisture in the tubes can cause the accumulation of mold, algae and bacteria, which will not only shorten the life of the equipment, but also be harmful to our health. In addition, the cleaning of the oxygen mask is extremely important. In order to solve Joe's problems better and faster, we recommend that Joe send us the overall picture and drawings of the product and the application. After receiving Joe's information, we told Joe that we customized the spring deluxe flexible stainless cpap tube cleaning brush slimline and the small bottle brush set. The spring brush cleans the CPAP tube and the vial brush ensures the mask to be clean. For the spring brush we use 304 spring, the small bottle brush also uses stainless steel skeleton to prevent rust. The bristle is made of pure nylon it ensures that the inner of the CPAP tube or the mask is not scratched, and have good cleaning performance. The brush head is processed in a pair of folds and it’s a fan shape, so it can reach the concave and convex parts of the ventilator tube for thorough cleaning. Joe is very satisfied with our solution and said that he is looking forward to receiving our samples. After 15 days, we successfully completed the sample and arranged it for Joe. A month later, we sent an email to Joe and he told us that this deluxe flexible stainless cpap tube cleaning brush slimline set is perfect and practical. After the CPAP brush set was put into the market, the feedback was good and he received many customers' favor. Subsequently, Joe placed us an order for the 1000 units.

read more

Some time ago we received an inquiry from Mr. Chen from Guangzhou. He said he wanted to buy a cleaning brush for his CPAP tube. Mr. Chen said that he used a normal cleaning brush to clean it, but it was time consuming and laborious, and it was not clean enough. He asked if we can provide a Deluxe flexible stainless cpap tube cleaning brush slimline. We told Mr. Chen that the Deluxe flexible stainless cpap tube cleaning brush slimline we produced was exported overseas and the quality is guaranteed. There is no problem for him. Subsequently, Mr. Chen sent us the product images, specifications of the CPAP tube. After we saw it, we learned that this CPAP tube purchased by Mr. Chen is very long and has a small inner diameter of 15mm that we produced before. We told Mr. Chen that we will match the CPAP tube brush with a length of 1.8m and an inner diameter of 15mm. The handle is made of stainless-steel wire, which can be bent as small as palm and packed into a bag for easy carrying. It can stretch to the longest length and cleans the entire CPAP tube when need. The brush is made of pure nylon and is perfectly combined with stainless steel to clean the inside of the CPAP tube multiple times without penetrating the CPAP tube brush. Mr. Chen said that he was looking forward to receiving our samples. After 10 days, we successfully completed the sample and sent the CPAP tube brush to Mr. Chen. After a month, we called Mr. Chen and he said that the Deluxe flexible stainless cpap tube cleaning brush slimline fit the tube perfectly and can be thoroughly cleaned the inside of the CPAP tube. It is important to save time. His customer feedback is also very good. A week later, we received an order of 5,000 units from Mr. Chen.

read more

After receiving email feedback from customers who came to Jack in March, the surgical brush price ordered from other countries were not only clean and clean, but also scraped the equipment, resulting in the return of the goods by customers, and demanded that a batch of qualified surgical brush price be purchased as soon as possible. Our sales customer service Mary responded in time 1 minute after receiving the customer email, and Jack learned about the size of the previous surgical brush price. It turns out that the brush bristles purchased before are very hard and non-nylon silk, and it is easy to scratch the endoscope with a little force in the cleaning process, but if it is not forced and the cleaning is not in place, in addition, the shearing used in the head treatment. Mary told Jack that it must be produced with pure nylon wool, soft and not scraping equipment, and that the head treatment needs to be made with glue. Jack is very interested in Mary's suggestion and pays for the customization of usd90 samples. We will send the sample in three days . Two days later, Jack received samples of surgical brush price, arranged tests for the first time, and found that they were very clean and could not scrape. They ordered 30, 000 surgical brush price directly from us.

read more

Mr. Li is the boss of a small commodity trading company and often helps foreign customers buy products on their behalf. In the last six months, the surgical brush price products purchased by foreign customers are very bad. After a period of customer use, the whole brush will show serious fork hair and can no longer be used. Customers are very dissatisfied. Through the search, Mr. Li found Mr. AOQUN, and Mr. Li heard Mr. Li's confusion, when he told Mr. Li:``AOQUN's flask test tube brush products were made of pure nylon wool, with a rebound rate of 99.9%, high-speed friction for 1 million times without deformation and no hair loss;Good aging resistance, no bending, can keep the performance intact under different environments, and the test tube applied with good tensile force produced by the group is good. The tensile force of every 5 hair wires is more than 3Kg, which greatly reduces the frequency of frequent replacement of the customer and saves the cost for the customer. ``Mr. Chestnut then offered a sample to Mr. Li. Ten days later, Mr. Li called Mr. Li and said, "the sample of surgical brush price provided by your company has been confirmed by customer testing. Through the use of the experiment, the elasticity is very good, and there is no more bending, hair loss and other phenomena, which proves that the quality is really guaranteed." On the same day, Mr. Li placed an order for 3000 surgical brush price.

read morescan to wechat

scan to wechat