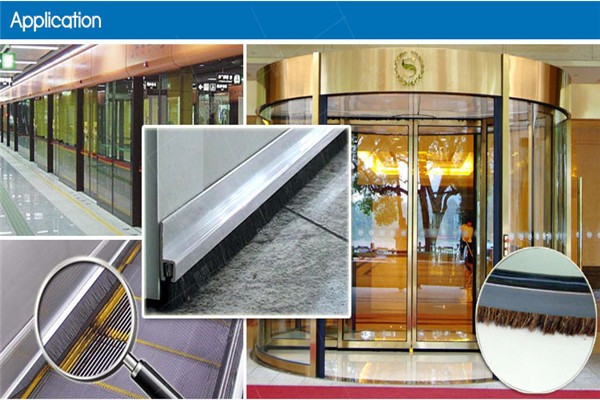

Recently, I received an inquiry from Olesandra of Ukraine: the defective rate of the door frame sealing brush I purchased before is as high as 3%. Because only the dealers supply the good to me, and the defective rate cannot be reduced, which leads to our customers' complaints and reduced orders. Can you provide metal back strip brush with low defective rate? After learning about Olesandra's requirements, we introduced our company to him. "AOQUN is a manufacturer with 11 years of experience in manufacturing door frame sealing brush strips. The defective rate of products is controlled within 0.3% for a long time, and the quality is approved by customers. And we have our own internal quality inspection standards, the goods shipped with the inspection report. Please tell us the standard of your metal back strip brush and we will provide you with a suitable solution. Olesandra immediately sent us the information he requested, and after confirming the solution we provided, he decided to try an order of 10,000 pieces. About two months later, we received Olesandra's call: "your door frame sealing brush is of good quality, and the defective rate is within 0.1%. Now there are no customer complaints, and the number of orders starts to increase. I hope you can become a long-term supplier of my metal back strip brush.

read more

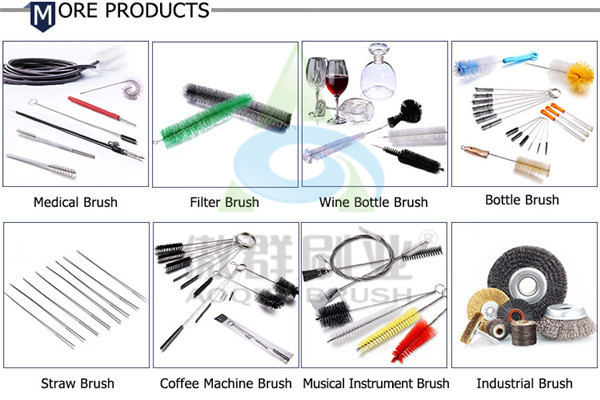

Alexander from Italy found our company through the official website and initiated an inquiry for us. He said they are dealers specializing in the sale of laboratory instruments on Amazon, and they want to purchase a batch of surgical cleaning brushes. He said that a batch of brushes they had previously purchased were complained by customers that the stainless steel was too soft, not easy to clean, and it was difficult to reverse the direction. After learning about the surgical cleaning brushes previously purchased by Alexander, we found that their previous brush diameter was 18mm, the total length was 250mm, and the diameter of a single stainless steel was only 1.0mm. The diameter and total length are too long, but the stainless steel is small, which will result in uneven distribution of the force, so the brush is difficult to control. We changed the diameter of the stainless-steel stem from 1.0mm to 1.2mm. With the increase of stainless steel, the hardness of stainless steel will increase, which will increase the hardness of the brush and better control. We sent the surgical cleaning brushes to Alexander. After receiving it, he gave us orders of 3,000. After receiving the test tube brush for a month, Alexander responded: "new customers did not complaint, and the old customers also praised us for better quality. The brush hardness is very good now."

read more

“Can you provide me with consistent thickness strip brush application?” Franklin, the purchasing manager of the Australian garage door manufacturer, wrote in the mail. Through the communication we knew that, Franklin's company purchased a batch of sealing brushes from a brush factory in China some time ago. Originally, if the quality of the brush was good, it should be able to be used normally. A serious problem was found in the brush when it was inspected. In addition to the thickness of the bristles did not meet the standards they require, the brush light leakage was also more serious. Therefore, Franklin wanted to find some qualified brush manufacturers in the Internet. The website of AOQUN deeply attracted him. As a brush manufacturer with 11 years of experience, AOQUN’s professional Anna made a commitment: "Please don’t worry, we will provide the best products to support you. "We first checked the location of the strip brush application, dimension, thickness requirements. Second, we made samples to ensure that the product meets the requirements, During the sample process, we will make relevant production records for the product information to ensure that the large products are consistent with the samples. At the end of the sample confirmation, Franklin sent us the first order after scrutinizing all the parameters of the product and checking the light leakage. When receiving the first 1800-meter order, Franklin also sent an email saying: "Not only me, our technicians are very satisfied with your strip brush application samples. I hope that you can also do the better for mass production. I believe we have tight cooperation in future."

read more

Culver from Germany sent us an enquiry through Alibaba. He said that they want to buy a surgical instrument brushes. They have also purchased it before, but the brush head they purchased before has scratched the bottom of the surgical instrument, causing them a great loss. We asked Culver to send us their previous surgical instrument brushes so that we could help them analyze the problem and better solve the problem. After receiving the Culver sample, we found that their previous brush was too thin, so that the head became thinner after getting wet, revealing the stainless-steel wire inside. When the surgical instrument brushes is used for cleaning, the stainless steel is in direct touch with the bottom of the surgical instrument and is scratched. We customized a brush for Culver with a 50% increase in filament thickness and sent it to him. Culver received feedback after receiving the samples. They liked our surgical instrument brushes. After the experiment, they found that the problem of scraping the bottom was solved and the brush head was very soft. They finally ordered us 3,000 brushes.

read more

I recently received an inquiry from Hassain of Paraguay: "my current strip brushes suppliers often fails to deliver the goods in time, which leads to the delay of my project and customer complaints and fines. I need to find a manufacturer who can deliver on time. I found you through the Internet search, can you help me solve the door under the seal brush on time delivery problem? We told Hassain: "we are a strip brushes suppliers with 11 years’ experience in producing door bottom seal brushes, with a monthly brush output of more than 500,000 meters. Compared with other dealers who can only rely on the strip brushes suppliers to decide the delivery date, we have an obvious advantage. We can also keep stock for our regular customers to meet their unplanned orders. In addition, in 2013, we provided the UAE customers with 100,000 pieces of customized door bottom seal brush within 10 days, the customer even came to the factory personally to appreciate us. We provided Hassain with the samples of the specifications he required. 7 days after confirming of our samples, Hassain placed a trial order of 2000 door bottom seal brushes. Two months passed, Hassain has placed three orders with us. He told us that we delivered the goods in time, his customer never complains him. He hopes that we can become his long-term strip brushes suppliers and keep inventory for him.

read more

Surgical wire brush are used as tools for cleaning surgical instruments, and the shaft material selection is also critical. If the quality of the material is poor, it may affect the cleaning effect, the results of the next experiment, and even may pose a safety hazard. Today we will talk about the importance of steel wire selection. It is well known that surgical wire brush is generally made of a combination of filament and steel wire. The steel wire of the brush generally are stainless steel, rubberized wire and iron wire. In the comparison of the three kinds of wires, the best quality is stainless steel, followed by the rubber line and the last wire. The instability of the wire will cause rust after a long time and multiple cleanings. If the rust falls or remains in the surgical instrument, many adverse consequences will occur. The rubberized line is a rubber sleeve on the basis of the iron wire to isolate the direct contact between the iron wire and the water, but the rubber layer outside the rubberized wire will be abraded after a lapse of time. The stability of the stainless-steel wire is the strongest and it is not easy to rust. AOQUN surgical wire brush is generally made of stainless-steel wire because it has the best stability, reduces safety hazards, and has a longer service life.

read morescan to wechat

scan to wechat